- We have a comprehensive approach to testing, which includes support in validation strategy, development of dedicated testing set-ups, time-optimized test execution, data processing and support in results interpretation.

- We deliver customized solutions that meet clients’ unique requirements.

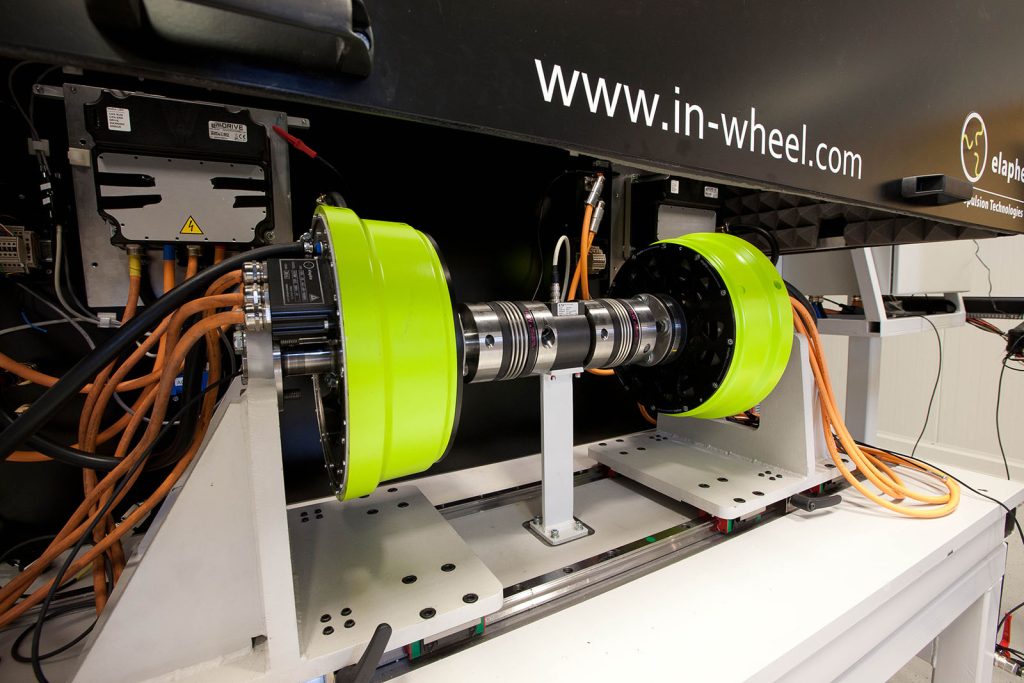

- Our modular measuring stations enable flexibility and quick adaptation to different requirements.

- Highly educated team members with universal knowledge and more than 10 years of experience in automotive testing.

- By working with us, you get access to wider company knowledge and support of different departments (electronics HW&SW, CAE, design engineering, machining).

- We provide 24/7 on-site monitoring.

- Less than 10 % of downtime at long-lasting tests.

Why Elaphe testing center

What we offer

- Testing services in the scope of the device under test (DUT) validation

- Support of validation plan preparation and execution according to different automotive standards (VDA, VW8000, GMW,…)

- Advanced performance testing for detailed DUT characterization

- Advanced environmental/endurance testing for better insight into DUT durability

- Engineering tests based on customer requirements

- Design and preparation of dedicated testing setups

- Testing infrastructure rental

Portfolio

Concept and design validation of the Endurance in-wheel propulsion system with the main focus on mechanical and endurance testing. Engineering development validation of specific parts.

Thermal and endurance testing of the inverter.

Detailed performance testing in the scope of concept validation, where few R&D iteration loops were done. Complete design validation testing of the Lightyear 0 propulsion system.

Thermal and endurance testing of the inverter

Powerful data acquisition systems with extremely high sampling rates are used for detailed power and NVH measurements. Advanced software enables both data acquisition and/or test set up control with quick adaptation to specific customer needs.